Project Mosquito's

Tony and John have built a pair of Mosquito's based on Ex team member Ivan's original design as a tribute to him following his passing. The project has taken several years as work has progressed in between other projects.

The original model was electric powered but these 2 are powered by DLE55cc engines. Some areas of the model needed to be redesigned to cope with the loads and vibration of the ic engines and the increased flying loads. John did the redesign and Alan cut the parts on the team's CNC machines. The build was split between Tony and John with Tony building the fuselages and tails and John building the wings and undercarriage. The basic airframe components were then brought together and the builds completed as a joint effort.

The models have working bomb doors and bomb releases, They also have flashing machine guns and cannons and full Nav and landing lights.

Scale 1/5th

Wingspan 2.7m

Length 3.3m

Weight 20.3kg

Work started by making the complex undercarriages and attaching them to the motor boxes

Kits of parts were cut out by Al on the teams CNC machine

Wings were constructed around the motor boxes

Sheeting the first half shell.

Sheeting added to the second side

Fuselages were built as half shells and then put in a support cradle for joining and sheeting of the second side

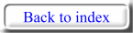

Trial fitting the engine. DLE 55RA's were chosen, they are much bigger than required but will allow big 3 blade props to be turned and due to their power, they can be operated at lower revs than smaller motors and still produce sufficient power.

Homemade multi chamber silencers will be fitted to fit in the cowlings and make the motors quiet.

Trial fitting of the cowlings onto the wing.

Scale detail being added. Fineline tape and high build filler is used to make the panel lines. Cast resin exhausts have also been fitted.

Adding panel lines and detail to the wing.

Masking up for the canopy frame which was sprayed onto the canopy with high build primer.

Home made silencers were fabricated to fit in the cowlings

Fitting the resin moulded exhausts to the cowling

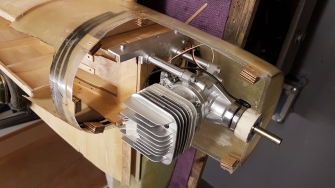

Motor fitted and cowlings painted

Painting almost finished

In its natural element.

Job done. Now it is time to enjoy flying them together