Grumman Albatross Flying Boat

This Ghost Squadron project started almost by accident when the team acquired a fiberglass fuselage that had been made for a film contract that appears to have never been produced.

The fuselage was in a poor state but John felt that it would be possible to make a flying model from it so work started to gather as much info as possible to complete the model. Further resurch uncovered some undercarriage parts and part built wings and although these were not really suitable for the flying model they could be used to design suitable structures for a fully functioning flying model.

The wings and tail were constructed traditionally from balsa and ply and then glass skinned and work progressed quite quickly. It had been decided from the start to try to make the model ambhibious and this required great thought throughout the build to ensure the model would be waterproof.

The real challenge on this model has been the very complicated retracting main undercarriage legs. The design and operation of these legs has caused much head scratching throughout the build on the model and various options have been tried to get successful and reliable retraction and extension. After trying several pneumatic solutions which failed to perform satisfactorily John developed a hydraulic solution and this has delivered a very scale retraction and extension of all 3 wheels and Al constructed a custom electronic sequencer to control the complex retraction sequence.

Wingspan 5m

Weight 41 kg

Engines 2 x Zenoah 62cc

Futaba radio

Construction underway. The complex undercarriage part fixed to the fuselage and part to the wing can be seen

Another picture of the complex udercarriage showing the folding leg and lock part way up the leg. The wheel folds into the fuselage recess and the leg into the slot in the fuselage and wing.

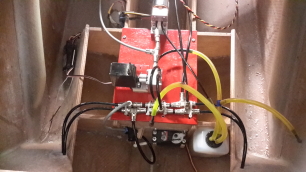

Hydraulic system for raising and lowering the undercarriage.

Fuselage hanging from the washing line being painted.

Disaster with the painting of the complex logo on the tail. This had to be all sanded off and work start again.

Second attempt at painting the logo. Interestingly the same logo on the other side of the tail painted with no problems !!!

First outing to start the test flying. First flights were done with 2 blade props.

First flight

Wheels up beat up of the field.

First water trials

Taxiing around the lake. The model has no water rudder so steering is via differential throttle control mixed into the rudder channel. Left rudder also opens up the right motor and vice versa. After adjustment of the mixing ratios this proved to be a reliable mathod of steering the model....but switch it out before take off !!!!

Well, that did not go quite as planned ! Failure of the sheeting on the top of the nose gear wet well due to water pressue caused the fuselage to flood.

All dried out and flying again